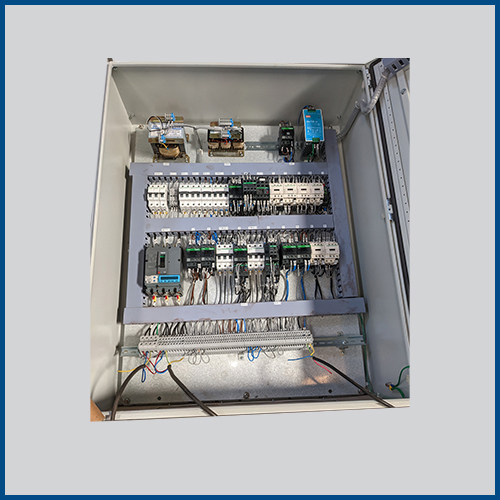

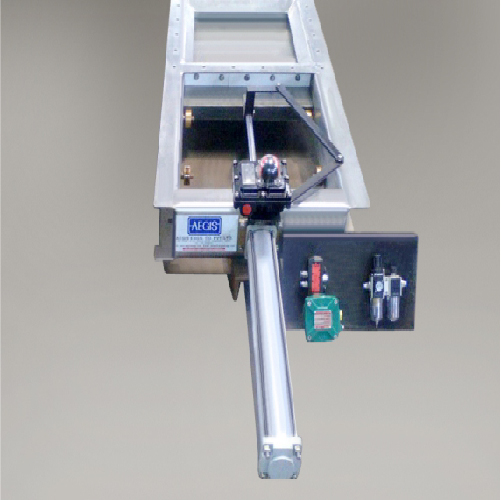

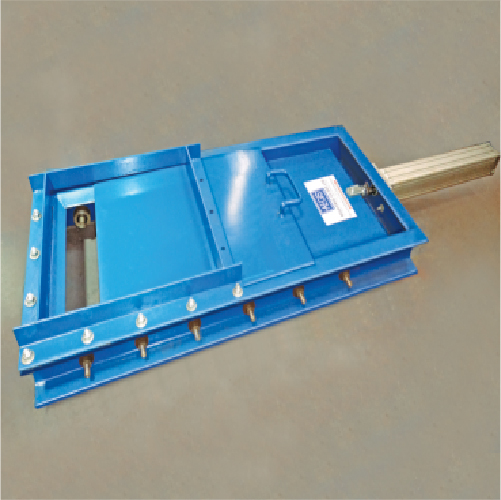

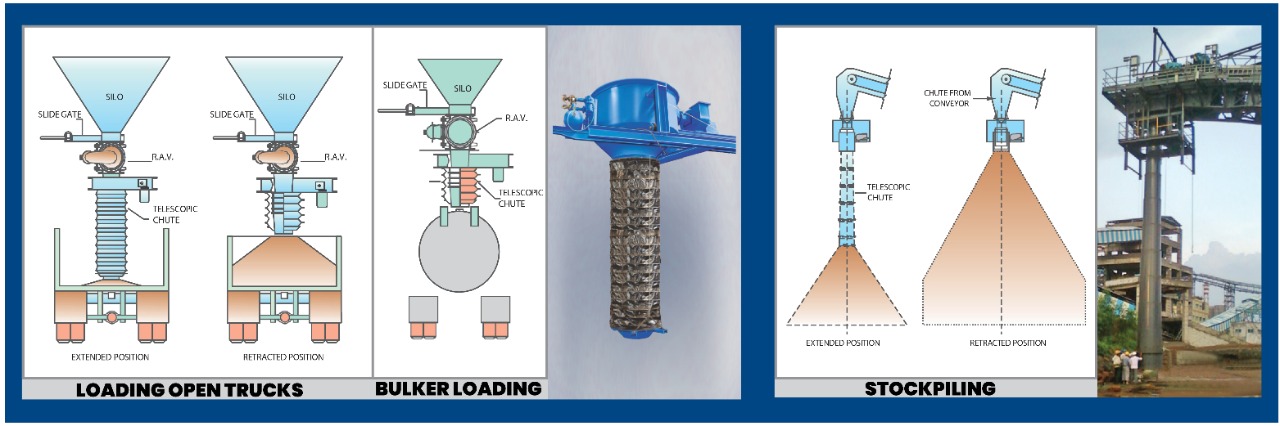

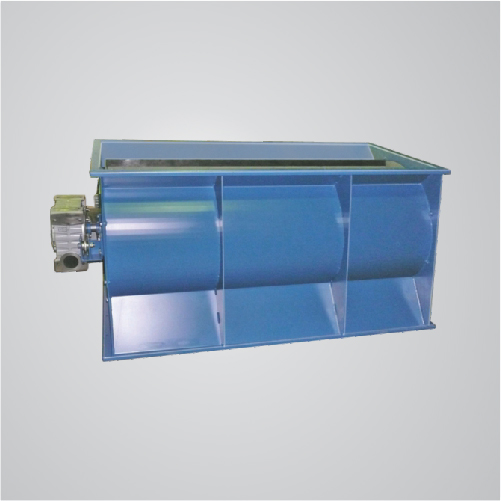

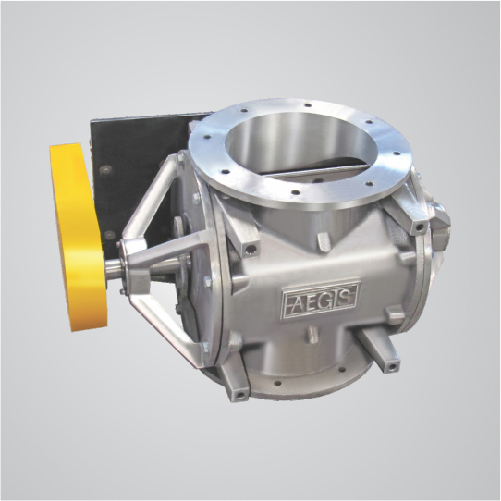

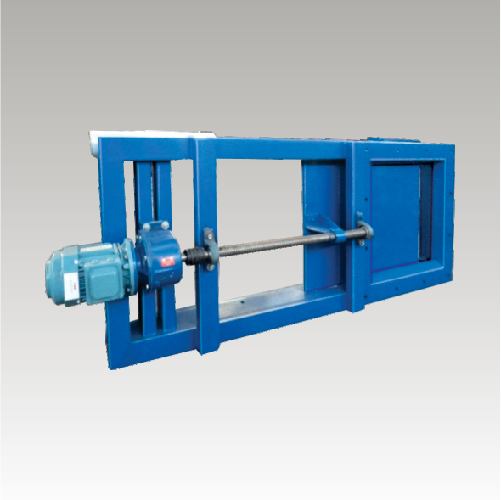

Telescopic loading spout are conceived and designed in house. High quality inputs like steed plates/sheets, alloy steel bar material are fabricated /machined and assembled by skilled manpower along with quality bought out items like electric motor/gearbox, instruments, bellows, panel board and many more. Attention is given to minutest detail to ensure reliable & trouble free operation.

Equipments are manufactured using good manufacturing practice.